Product Description

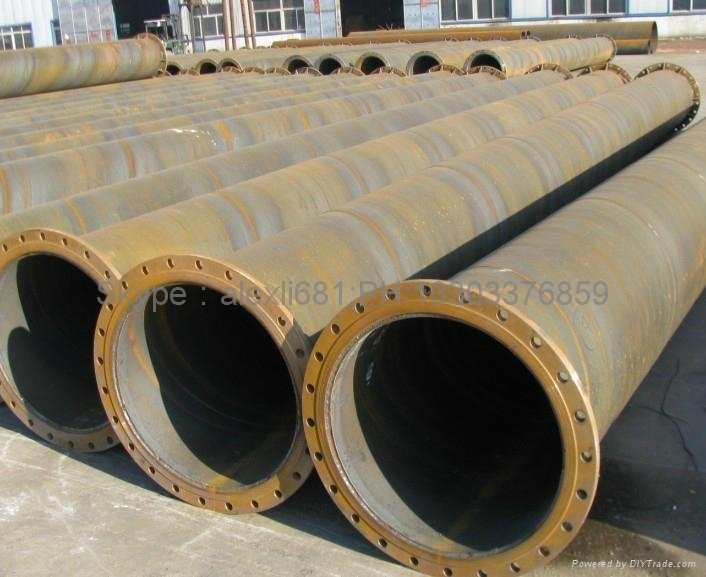

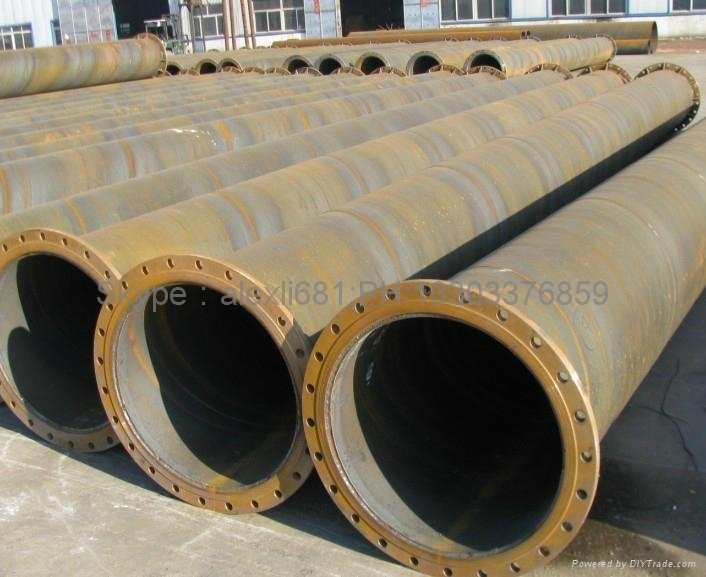

Spiral tube

Spiral pipe is also called the spiral steel pipe or spiral welded pipe, is the low carbon structural steel and low alloy steel strip according to certain helix Angle (called forming Angle) rolled into a tube blank, and then welded pipe joints made up, it can use a narrow strip in the production of large diameter steel pipe.Major manufacturing technology is a double-sided submerged arc welding, spiral pipe is mainly used in oil, natural gas pipeline, its specification in diameter * wall thickness.Spiral pipe has one side welding and welding by both sides, welded pipe shall ensure that the water pressure test, the tensile strength and cold bending properties of the weld in accordance with regulations.

Characteristics of spiral pipe: straight seam welded pipe production technology is simple, high production efficiency, low cost, rapid development.The strength of the spiral welded pipe is generally higher than straight seam welded pipe, use a narrow billet production of larger diameter welded pipe, you can also use the same width of billet in the production of different pipe diameter welded pipe.Liaocheng city jia bin supply spiral pipe steel pipe co., LTD.But compared with the same length of straight seam pipe, weld length by 30 ~ 100%, and the production speed is low.As a result, a small diameter welded pipe are mostly with straight seam welding, large diameter welded pipe for the most part adopts spiral welded.

Now commonly used standards of the spiral pipe can be divided into: the SY/T5037-2000 (solid, also known as the common fluid conveying pipe with spiral seam submerged arc welding steel pipe), GB/T9711.1-1997 (national standard, also known as oil and gas industry conveying pipe delivery technical conditions in the first part: grade A steel tube strict (so far have GB/T9711.2 grade B steel pipe)), API 5 l (American petroleum institute, also known as the pipeline steel pipe; which can be divided into PSL1 and PSL2 two levels), SY/T5040-92 (pile with spiral seam submerged arc welding steel pipe).

classification

Pressurized fluid conveying with spiral seam submerged arc welding pipe is mainly used for conveying oil, natural gas pipeline, pipe pressure ability strong, good plasticity, easy to welding and processing molding;Generally low pressure fluid conveying spiral seam submerged arc welding steel pipe adopt double automatic submerged arc welding or welding by one side into the legal system for water, gas, air and steam general low-pressure fluid conveying with submerged arc welding steel pipe.

The production process

1) raw material namely strip coil, wire, flux.Have to pass strict physical and chemical inspection before investment.

2) strip head to tail docking, use single or double wire submerged arc welding, after rolled steel tube adopts automatic submerged arc welding repair welding.

3) before forming, strip after flattening, cutting edge, edge planing, transmission and cleaning the surface to the flanging process.

4) on both sides of the electric contact pressure gauge control conveyor under the pressure of oil cylinder pressure, ensure the smooth delivery of strip steel.

5) the use of external control or internal control roll forming.

6) the weld gap control device to ensure that meet the requirements of welding seam clearance, pipe diameter, the wrong side of the amount and weld gap are tightly controlled.

7) welding and welding are used within the United States Lincoln welding machine for single or double wire submerged arc welding, to obtain the stable welding specification.

8) after welding the weld passes the online continuous ultrasonic automatic meter check, ensure the spiral weld nondestructive testing coverage of 100%.If there are defects, automatic alarm and spray tags, production workers to adjust process parameters, in a timely manner to eliminate defects.

9) by air plasma cutting machine to cut the steel tube into single.

After 10) cut into single pole, the head of every batch of steel pipe should be strictly check system, check the weld mechanical properties, chemical composition, amalgamation, steel tube surface quality and the nondestructive flaw detection, ensure that qualified pipe process, can be formally put into production.

11) have continuous acoustic detection of weld mark parts, after manual ultrasonic and X-ray check, if there are defects, after repair, again through the nondestructive inspection, until defects have been eliminated.

12) strip steel butt weld and fellowship with spiral weld d joint in the tube, all pass X-ray films and television inspection.

13) each steel pipe after hydrostatic pressure test, radial sealing for the pressure.Test pressure and time are controlled strictly by steel pipe hydraulic microcomputer testing device.The parameters automatically printed out.

14) pipe end machining, make the end verticality, slope Angle and the blunt edge to get accurate control.

Surface treatment:

1, cleaning: used solvent, emulsion cleaning steel appearance, to get to remove oil, grease, dust, smooth agent and similar organic matter, but it means less steel appearance of rust, scale removal, welding flux, etc., thus the tricks only as adjuvant in corrosion produced.

2, cleaning things: first, using of steel wire brush, etc polished appearance, can remove loose or cock scale, rust, slag, etc.Open hand tools derusting to Sa2 level, dynamic things rust removal can be reached level Sa3, if sheet steel surface adhesion strong oxidation, cleaning result ignored wants, anchor pattern depth of anticorrosion construction requirements.

3, pickling: regular use of chemical and electrolytic pickling treatment of two different ways to do, use only pipeline anticorrosion chemical pickling, can remove scale, rust, old coating, sometimes can be used as remarketing after sandblasting derusting.Chemical cleaning is can make the appearance to the inevitable and coarse degree of cleanliness, but its anchor lines shallow, and easy to form pollution situation.

4, spray (cast) shot derusting: shot derusting spray (cast) is a high power motor drive the spray (cast) blade high-speed twist, make steel shot, steel grit, wire section, minerals and other abrasive under the centrifugal force effect on steel tube appearance spray (cast) disposal, not only can completely eliminate rust, oxides and dirt, and the effect of steel tube in the fierce impact and friction abrasive, can reach the requirements of coarse degree on average.

Steel pipe role

Large pipe used for conveying fluid, such as oil, natural gas, water, gas, steam, etc., in addition, doing bending and torsional strength phase at the same time, the weight is lighter, it is widely used in the manufacture of machinery parts and engineering structures.Also commonly used for the production of various kinds of conventional weapons, barrel, shells, etc

Steel pipe classification

Steel pipe seamless steel pipe and welded steel pipe (tube) two kinds big.According to the cross section shape and can be divided into circular tube and special-shaped tube, steel tube is widely used, but there are some square, rectangle, semicircle, hexagonal, equilateral triangle, octagonal special-shaped steel tube.For fluid under pressure steel pipe are hydraulic experiment was carried out to test the compression ability and the quality, under the pressure of regulation does not leak, soaked or expansion of qualified, some steel pipe according to the standard or the buyer requires edge test, flaring test, flattening test, etc.

Payment Terms︰

TT

Product Image